The Science Behind Carbon Fiber: Why It’s Perfect for Car Wraps

Carbon fiber is a lightweight and incredibly strong material that has gained significant popularity in various industries, including automotive, aerospace, and sports equipment. When it comes to car wraps, carbon fiber offers unique advantages that make it an ideal choice for enhancing a vehicle’s aesthetics and performance. The science behind carbon fiber lies in its composition and manufacturing process, which contributes to its exceptional properties.

1. Composition

Carbon fiber is composed of thin, long strands of carbon atoms, typically in the form of crystals aligned parallel to the fiber’s longitudinal axis. These carbon fibers are combined to form a fabric-like material. The fibers are then embedded in a polymer matrix, often epoxy resin, which binds them together, creating a strong and rigid structure.

2. High Strength-to-Weight Ratio

One of the key reasons why carbon fiber is perfect for car wraps is its impressive strength-to-weight ratio. Carbon fiber is significantly lighter than traditional materials like steel or aluminum while being remarkably strong. This characteristic not only reduces the overall weight of the car but also enhances its structural integrity, making it more resistant to impacts and stress.

3. Rigidity and Stiffness

Carbon fiber’s unique arrangement of carbon atoms provides exceptional rigidity and stiffness. This property ensures that the car wrap maintains its shape and structure without flexing excessively. This is particularly advantageous for car owners looking to give their vehicles a sporty and aggressive appearance.

4. Flexibility and Conformability

Despite being rigid, carbon fiber car wraps are also designed to be flexible and conformable. Skilled installers can mold the wrap to fit the intricate curves and contours of the vehicle’s body, ensuring a seamless and sleek finish.

5. Thermal Conductivity

Carbon fiber exhibits excellent thermal conductivity, meaning it can efficiently dissipate heat. This characteristic is beneficial for cars as it helps in preventing heat buildup, especially in areas like the engine bay or exhaust regions. Additionally, it can reduce the risk of thermal damage to the underlying car paint.

6. Corrosion Resistance

Unlike metals, carbon fiber is inherently corrosion-resistant. This makes it an ideal choice for protecting the vehicle’s surface from rust, oxidation, and other environmental elements that can degrade the appearance and integrity of the car.

7. Design Freedom

Carbon fiber car wraps come in a variety of styles, patterns, and colors, allowing car owners to customize their vehicles according to their preferences. Whether you desire a classic carbon fiber weave look or something more modern and abstract, the design possibilities are extensive.

8. Endurance and Longevity

When properly cared for, carbon fiber car wraps can retain their appearance and functionality for an extended period. They are resistant to fading, UV damage, and other environmental factors, ensuring that your vehicle maintains its head-turning appearance for years to come.

In conclusion, the science behind carbon fiber, with its exceptional strength, lightweight, rigidity, and aesthetic appeal, makes it an ideal material for car wraps. Its versatility and performance characteristics not only enhance the overall look of the vehicle but also contribute to improved durability and protection.

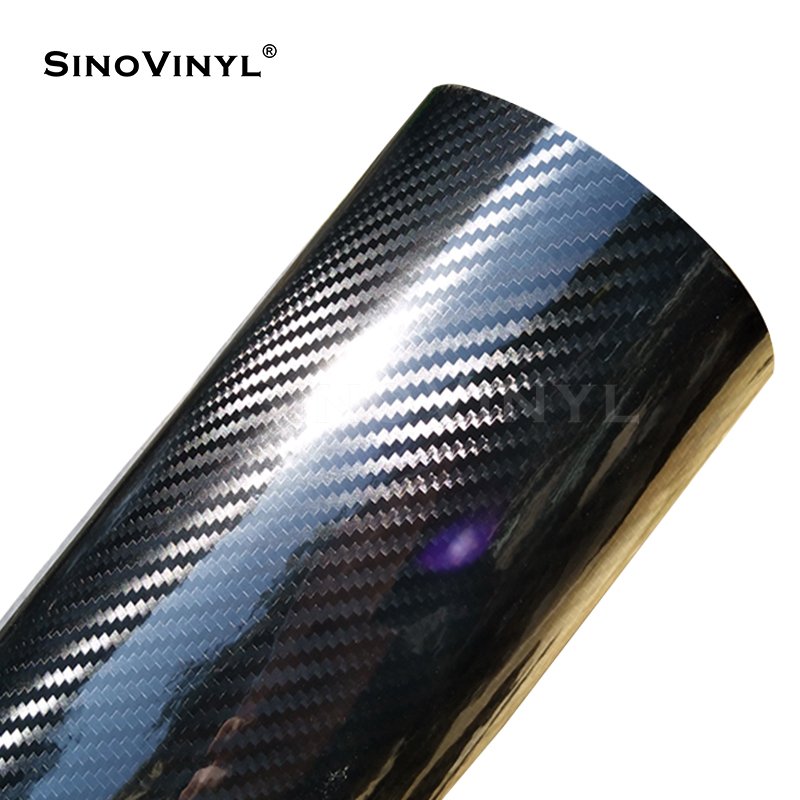

Differentiating 3D vs. 5D Carbon Fiber Car Wraps: What Sets Them Apart?

Carbon fiber car wraps have gained immense popularity among auto enthusiasts for their sleek appearance and added protection to the vehicle’s paintwork. Two common types of carbon fiber car wraps are 3D and 5D, each offering unique features and benefits. Understanding the differences between these two options can help car owners make an informed decision when choosing the right wrap for their vehicles. Let’s delve into what sets 3D and 5D carbon fiber car wraps apart:

1. Material Thickness

– 3D Carbon Fiber Wrap: This type of wrap has a moderate thickness, usually around 0.15mm to 0.18mm. It offers a subtle textured look, adding a touch of elegance to the car’s appearance without being overly pronounced.

– 5D Carbon Fiber Wrap: In contrast, the 5D carbon fiber wrap is slightly thicker, typically ranging from 0.20mm to 0.25mm. This increased thickness contributes to a more pronounced and dynamic texture, making it stand out compared to 3D wraps.

2. Visual Depth

– 3D Carbon Fiber Wrap: While still providing a textured appearance, 3D wraps exhibit a relatively flatter and smoother surface compared to their 5D counterparts. The visual depth is more understated and sophisticated.

– 5D Carbon Fiber Wrap: With its added thickness and texture, the 5D carbon fiber wrap creates a more striking and pronounced visual depth. This enhanced 3-dimensional effect captures and reflects light, giving the car a bolder and sportier look.

3. Flexibility and Conformity

– 3D Carbon Fiber Wrap: Due to its moderate thickness, 3D wraps offer good flexibility and are relatively easier to apply, conforming to the curves and contours of the vehicle’s surface smoothly.

– 5D Carbon Fiber Wrap: The slightly increased thickness of 5D wraps can make them a bit less flexible compared to 3D wraps. Though still conformable, they might require more skill and expertise during installation to ensure a seamless fit.

4. Durability and Protection

– Both 3D and 5D carbon fiber wraps provide a protective layer that shields the car’s original paint from light scratches, UV rays, and minor abrasions. The durability of the wraps largely depends on the quality of the materials and installation techniques.

5. Price Point

– Generally, 5D carbon fiber wraps tend to be slightly more expensive than 3D wraps due to their increased thickness and visual impact. The price difference, however, might vary depending on the brand and supplier.

In summary, the choice between 3D and 5D carbon fiber car wraps boils down to personal preference and the desired visual effect. If you prefer a sleek and refined appearance, 3D wraps may be the ideal choice. On the other hand, if you seek a more dynamic and eye-catching look, 5D wraps offer a bold and textured finish. Whichever option you choose, both 3D and 5D carbon fiber wraps are sure to elevate your car’s elegance and style.

Advantages of 5D Carbon Fiber Vinyl Wraps: Durability and Performance

1. Enhanced Protection

5D carbon fiber vinyl wraps provide an additional layer of protection for your car’s original paint. They act as a shield against minor scratches, stone chips, and UV rays, preserving your car’s exterior and maintaining its resale value.

2. Longevity

Compared to other types of vinyl wraps, 5D carbon fiber wraps are known for their exceptional durability. The high-quality materials used in their construction ensure they can withstand various weather conditions, including rain, snow, and extreme temperatures, without fading or deteriorating over time.

3. Resistance to Fading

The advanced manufacturing process of 5D carbon fiber wraps ensures that they are highly resistant to fading caused by prolonged sun exposure. This means your car will maintain its glossy and vibrant appearance for an extended period.

4. Flexibility and Conformity

5D carbon fiber vinyl wraps have excellent flexibility, allowing them to conform seamlessly to the contours of your car’s body. This feature ensures a smooth and precise installation, minimizing the risk of bubbles, creases, or uneven surfaces.

5. Lightweight

Despite its visually impressive texture, 5D carbon fiber wraps are lightweight. Unlike traditional carbon fiber panels, which can add significant weight to your vehicle, these wraps allow you to enjoy the aesthetics of carbon fiber without compromising the car’s performance or fuel efficiency.

6. Improved Aerodynamics

The smooth surface of 5D carbon fiber wraps can help improve the aerodynamics of your car by reducing drag. This enhancement may lead to better fuel efficiency and overall performance on the road.

7. Customizable Look

5D carbon fiber wraps offer a wide range of color and texture options, allowing you to customize your car’s appearance according to your preferences. You can choose from various carbon fiber patterns and colors to give your vehicle a unique and eye-catching style.

8. Easy Maintenance

Cleaning and maintaining 5D carbon fiber wraps is relatively simple. Regular washing with a mild car shampoo and water will keep the wrap looking fresh and clean, requiring less effort compared to polishing and waxing traditional paint jobs.

9. Cost-Effective Solution

Opting for a 5D carbon fiber vinyl wrap is often more cost-effective than painting your car with genuine carbon fiber panels. It allows you to achieve the sleek carbon fiber look at a fraction of the cost while still enjoying the added benefits of protection and performance.

10. Reversible Modification

Unlike permanent paint jobs or physical modifications, 5D carbon fiber wraps can be easily removed without causing damage to the original paint. If you decide to change the look of your car or revert to the factory finish, the wrap can be taken off, revealing the pristine paint underneath.

Overall, 5D carbon fiber vinyl wraps offer a durable and high-performance solution for car enthusiasts looking to enhance their vehicle’s appearance while ensuring it remains well-protected and retains its value in the long run.

Step-by-Step Guide: How to Apply 5D Carbon Fiber Car Wrap Vinyl Film

Applying 5D carbon fiber car wrap vinyl film can be a challenging task, but with careful preparation and attention to detail, you can achieve a professional-looking finish. Here’s a step-by-step guide to help you through the process:

Materials Needed

1. 5D carbon fiber car wrap vinyl film (ensure you have enough to cover the entire car)

2. Heat gun or hairdryer

3. Squeegee or application tool

4. Cutting tool (e.g., utility knife or razor blade)

5. Isopropyl alcohol and a clean cloth

6. Heat-resistant gloves (optional but recommended)

Step-by-Step Guide

Step 1: Clean and Prepare the Surface

Ensure your car’s exterior is clean and free from dirt, dust, and debris. Wash the car thoroughly and use isopropyl alcohol to remove any remaining residues. Make sure the car is completely dry before proceeding.

Step 2: Measure and Cut the Vinyl

Measure the surface area you want to wrap carefully. Add some extra inches to your measurements to have room for adjustments and trimming. Unroll the 5D carbon fiber vinyl film and cut it according to your measurements, leaving enough material to cover the edges of the car.

Step 3: Peel off the Backing

Start peeling off a small section of the backing from the vinyl. Be careful not to touch the adhesive side to avoid leaving fingerprints.

Step 4: Apply the Vinyl

Align the peeled edge of the vinyl with the target area on your car. Work slowly and methodically, pressing the vinyl onto the surface while ensuring it is straight and wrinkle-free. Use a squeegee or an application tool to smooth out the vinyl and push out any air bubbles.

Step 5: Use Heat to Mold the Vinyl

As you progress, use a heat gun or hairdryer on a low setting to heat the vinyl. Gently stretch the vinyl if needed to accommodate curves and contours of your car’s body. The heat will make the vinyl more pliable and easier to work with.

Step 6: Trim Excess Vinyl

Once the main areas of your car are covered, use a cutting tool to trim off the excess vinyl along the edges. Be cautious when cutting near car emblems or other delicate parts.

Step 7: Wrapping Tricky Areas

For more complex areas like bumpers, door handles, and side mirrors, use heat to soften the vinyl and carefully mold it around these features. Take your time and be patient to achieve a smooth and professional finish.

Step 8: Final Check and Finishing Touches

After wrapping the entire car, inspect the surface for any air bubbles, wrinkles, or uneven edges. Use the heat gun and squeegee to make any necessary adjustments. Smooth out any imperfections and ensure the vinyl adheres properly to the car’s surface.

Congratulations! You have successfully applied 5D carbon fiber car wrap vinyl film to your vehicle. Remember that the process may take some time and practice to master, so don’t rush and be prepared to make adjustments along the way. Always follow the manufacturer’s guidelines for the specific vinyl product you are using.

Final Words

In conclusion, 5D carbon fiber car wrap vinyl film embodies the perfect fusion of elegance and practicality, making it an ideal choice for passionate auto enthusiasts seeking to elevate their vehicle’s aesthetics. The mesmerizing depth and texture of carbon fiber, combined with the ease of application and durability of 5D technology, create a transformative experience for car owners. Whether you’re looking to enhance your car’s appearance, protect its original paint, or make a bold statement on the road, 5D carbon fiber wraps offer a customizable and head-turning solution. Embrace the future of car customization and unlock the boundless possibilities of carbon fiber elegance with 5D car wrap vinyl – an investment that not only leaves a lasting impression but also preserves the cherished beauty of your beloved automobile for years to come. Indulge in the allure of carbon fiber refinement, and let your car become a masterpiece on wheels with 5D car wrap vinyl film.